Using custom fixed asset labels is essential for businesses of all sizes to track and manage their assets efficiently. These labels provide a unique identification number and basic information about the asset, such as its location and usage history. However, choosing the correct printing method for these labels can be a crucial decision.

In this post, we will explore two widely used printing methods for custom asset labels – laser printing and thermal printing – and compare their advantages, disadvantages, and suitability for different business needs.

Table of Contents

I. Overview of Laser Printing

Laser printing has been a popular choice for many businesses due to its precision and durability. The process involves using a laser beam to attract toner onto the label material, creating a permanent bond between the toner and the substrate.

Advantages of Laser Printing

- High-Quality Prints: Laser printers offer sharp prints with high resolution, allowing for precise text, barcodes, and graphics on asset labels. This ensures effortless readability during inventory management processes.

- Long-Lasting Labels: The heat used in laser printing creates durable labels that are resistant to moisture, UV exposure, smudging, and other environmental factors that could compromise their integrity over time.

Disadvantages of Laser Printing

- Costly Set-Up: Setting up laser printers can be expensive initially since it requires investing in specialized equipment that may not already be available in the office.

- Limited Material Compatibility: While laser printers work well with most standard label materials like paper or polyester film, there might be limitations when it comes to unique materials such as metalized or textured substrates.

II. Overview of Thermal Printing

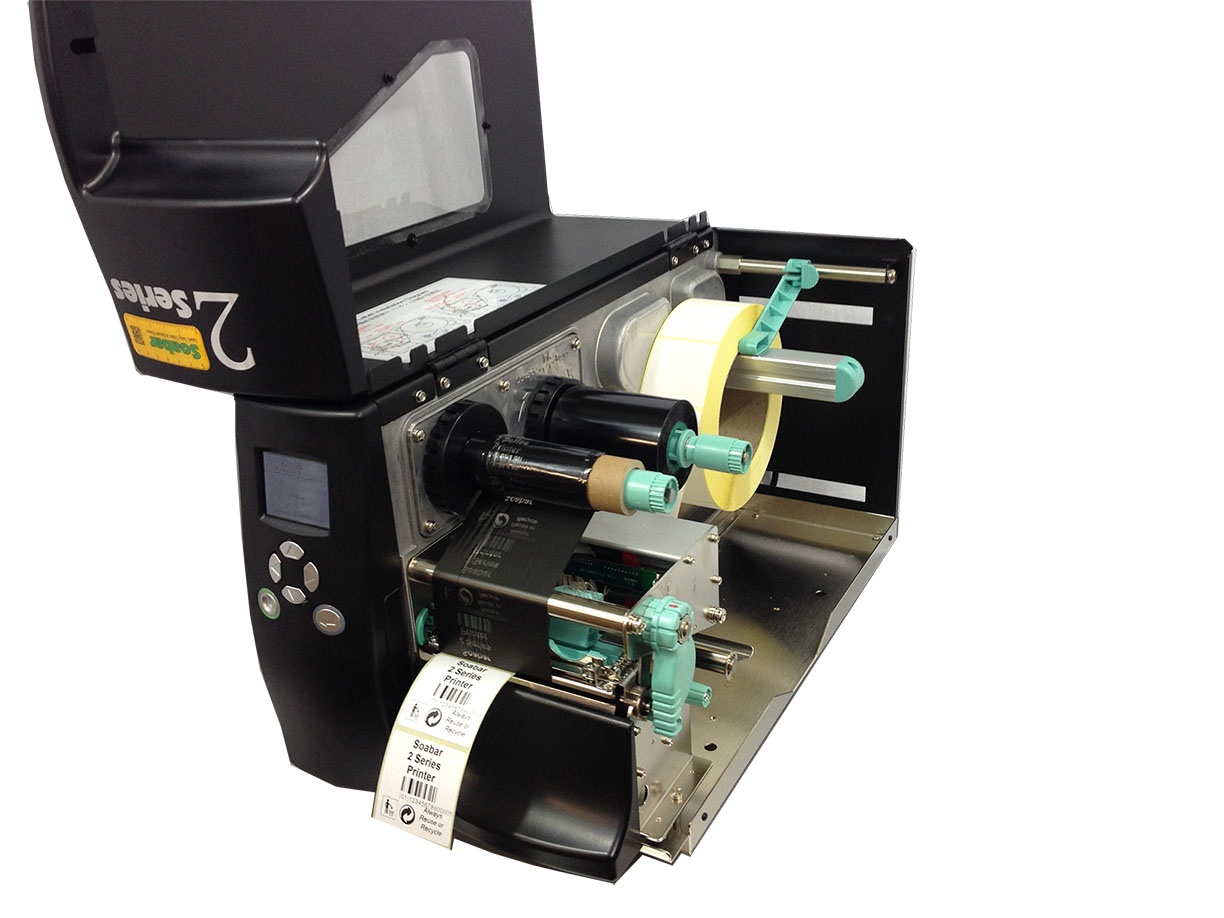

Thermal printing is another widely used method for creating custom fixed asset labels that offer simplicity and efficiency through direct heat transfer onto the specially coated label material.

Advantages of Thermal Printing

- Cost-Effective Solution: Thermal printers tend to have lower upfront costs compared to laser printers since they require less complex machinery.

- Quick and Efficient: Thermal printing does not require any consumables like inks or toners. Instead, the process relies on heat for printing, making it fast and ideal for high-volume label production.

Disadvantages of Thermal Printing

- Sensitivity to Environmental Conditions: Labels produced through thermal printing are more vulnerable to heat, sunlight, chemicals, and abrasion, which may result in fading or deterioration over time.

- Limited Print Resolution: Unlike laser printers, thermal printing usually offers lower print resolution and may not be suitable for labels with intricate details or small fonts.

III. Choosing the Right Method for Your Business

- Consider Printing Volume: If your business requires a large number of labels regularly, thermal printing might be the more practical choice due to its speed and efficiency.

- Assess Durability Requirements: Evaluate whether your assets will be exposed to harsh environmental conditions requiring labels with increased durability. In such cases, laser printing can provide better longevity.

- Analyze Label Design Complexity: If your asset labels involve intricate barcodes or small fonts that demand high-resolution printing, laser printers are better suited for achieving optimal readability.

IV. Considerations for Label Customization

Both laser and thermal printing methods offer different degrees of flexibility when it comes to customizing labels.

Laser Printing

Laser printers provide more options for customized label designs, allowing businesses to incorporate intricate logos, branding elements, and detailed graphics onto their asset labels. This level of customization can help enhance brand visibility and ensure consistency across various documents.

Thermal Printing

Thermal printers are better suited for simple and straightforward label designs that primarily focus on text, barcodes, and basic shapes. While they might be limited in terms of design complexity, they still offer enough customization options to meet most businesses’ asset-tracking needs.

- Ease of Integration with Existing Systems: When considering the printing method for custom fixed asset labels, it is essential to evaluate how well the chosen method integrates with existing systems or software used for asset management.Laser Printing: Laser printers often seamlessly integrate with standard office software programs like Microsoft Excel or asset management systems to handle batch printing or automated data processing efficiently.

Conclusion

When choosing between laser printing and thermal printing methods for custom fixed asset labels, each option has its own set of advantages and disadvantages to consider. Laser printing tends to offer higher print quality and durability but at a potentially higher cost, while thermal printing provides cost-effectiveness but may sacrifice some resilience in harsh conditions. Ultimately, the decision should be led by specific business needs, such as volume requirements, desired label longevity, design complexity considerations like barcode quality or font size demands of your custom fixed asset labels, and budgetary constraints.