Managing inventory effectively is critical for success in today’s highly competitive business environment. However, traditional inventory management methods are often complex, time-consuming, and need more visibility and control to optimize inventory levels and reduce costs.

This is where supply chain business analyst solutions come into play. By leveraging data analytics, machine learning, and artificial intelligence, these solutions can help businesses gain real-time visibility into inventory levels, forecast demand accurately, and optimize replenishment schedules to ensure that the right products are available in the suitable locations at the right time. For businesses looking to build more tailored solutions that align with their unique operational needs, exploring supply chain software development services can be a strategic move. These services allow organisations to implement highly customised tools that support better integration and decision-making across the entire supply chain.

In this article, we will explore the challenges that businesses face in inventory management, the benefits of supply chain analytics software solutions for inventory management, and the key features of these solutions. We will also examine a case study to illustrate the impact of fright management software solutions on inventory management in the retail industry. By the end of this article, readers will better understand how supply chain as a service solutions can help businesses optimize inventory levels, reduce costs, and improve overall supply chain efficiency.

Table of Contents

I. Challenges in Inventory Management

A. Limited Visibility And Control Over Inventory Levels

One of the most significant challenges in inventory management is limited visibility and control over inventory levels. Many businesses must track inventory accurately, leading to stockouts, excess inventory, and inaccurate demand forecasting. This can lead to increased costs and reduced profitability.

B. Difficulty In Balancing Inventory Levels With Customer Demand

Another challenge in inventory management is balancing inventory levels with customer demand. Businesses must optimize inventory levels to meet customer demand while minimizing excess inventory. However, with accurate demand forecasting, businesses may be able to achieve this balance, leading to lost sales or increased costs.

C. Complexities Of Managing Inventory Across Multiple Locations And Channels

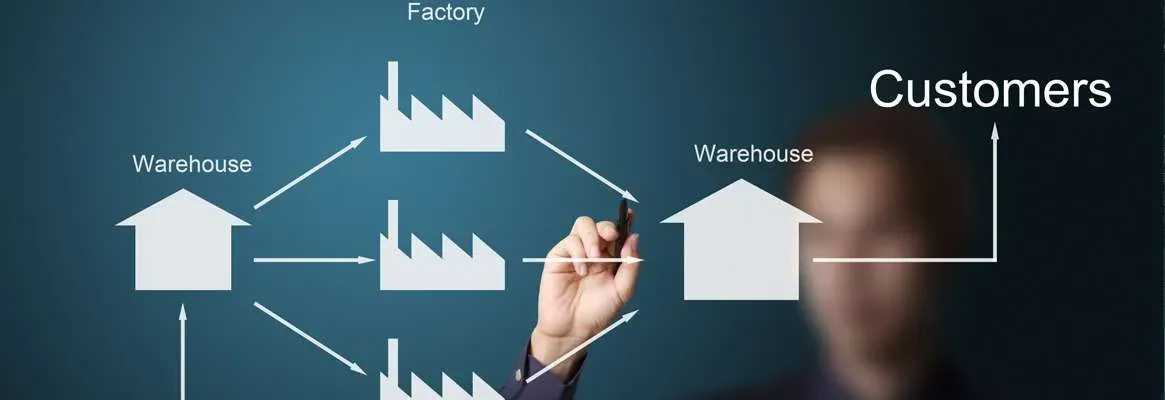

Businesses that operate across multiple locations and channels face significant complexities in managing inventory. They must ensure that the right products are available in suitable locations, at the right time, and in the right quantities. However, this can only be challenging with a centralized system for tracking inventory across multiple locations and channels.

D. Lack Of Integration Between Inventory Management And Supply Chain Planning

Finally, many businesses need more integration between inventory management and supply chain solutions planning. With a unified system, businesses may be able to align inventory levels with production and transportation schedules, leading to inefficiencies and increased costs.

II. Benefits Of Supply Chain Analytics Software Solutions In Inventory Management

1. Improved Accuracy And Reliability Of Inventory Data

One of the most significant benefits of supply chain visibility startups in inventory management is improved accuracy and reliability of inventory data. These solutions use real-time data analytics and reporting capabilities to track inventory levels, enabling businesses to optimize inventory levels and reduce the risk of stockouts and excess inventory.

2. Enhanced Demand Forecasting And Replenishment Capabilities

Supply chain analytics software solutions also offer enhanced demand forecasting and replenishment capabilities. These solutions use advanced algorithms and machine learning to analyze historical sales data and market trends, enabling businesses to forecast demand accurately and optimize replenishment schedules.

3. Better Visibility And Control Over Inventory Levels Across Multiple Locations And Channels

Another critical benefit of supply chain analytics software solutions is better visibility and control over inventory levels across multiple locations and channels. These supply chain visibility solutions offer multi-location inventory tracking and management features, enabling businesses to monitor inventory levels in real time and optimize inventory distribution across multiple locations and channels.

4. Increased Efficiency And Cost Savings In Inventory Management

Finally, transportation visibility software solutions can increase efficiency and cost savings in inventory management. Businesses can reduce carrying costs and improve inventory turnover by optimising inventory levels. Additionally, by aligning inventory levels with production and transportation schedules, businesses can reduce transportation costs and improve overall supply chain efficiency.

III. Key Features Of Supply Chain Analytics Software Solutions For Inventory Management

1. Real-Time Data Analytics And Reporting Capabilities

One of the key features of visibility software for inventory management is real-time data analytics and reporting capabilities. These solutions use advanced analytics tools to track inventory levels, monitor sales trends, and identify potential stockouts or excess inventory.

2. Demand Forecasting And Replenishment Planning Tools

Another critical feature of supply chain consulting firm is demand forecasting and replenishment planning tools. These solutions use advanced algorithms and machine learning to analyze historical sales data and market trends, enabling businesses to forecast demand accurately and optimize replenishment schedules to ensure that the right products are available in suitable locations at the right time.

3. Multi-Location Inventory Tracking And Management Features

Supply chain analytics software solutions also offer multi-location inventory tracking and management features, enabling businesses to monitor inventory levels across multiple locations and channels. These solutions provide real-time visibility into inventory levels, enabling businesses to optimize inventory distribution and reduce the risk of stockouts or excess inventory.

4. Integration With Supply Chain Planning Software

Finally, supply chain analytics software solutions for inventory management should integrate seamlessly with supply chain consulting services. By integrating inventory management with production planning and transportation management, businesses can optimize inventory levels, improve supply chain efficiency, and reduce costs.

IV. Case Studies

Reducing Inventory Costs And Improving Product Availability In The Retail Industry With Supply Chain Analytics Software Solutions

One example of the impact of supply chain visibility platform solutions on inventory management is in the retail industry. A major retail chain with over 2,000 stores across North America faced significant challenges in managing inventory levels and reducing costs. They needed more visibility into inventory levels and struggled to balance inventory levels with customer demand.

The retail chain implemented a supply chain software engineer solution to improve inventory management. The solution provided real-time data analytics and reporting capabilities, enabling the retail chain to track real-time inventory levels and sales trends. Additionally, the solution offered demand forecasting and replenishment planning tools, enabling the retail chain to forecast demand accurately and optimize replenishment schedules.

As a result of implementing the supply chain optimization software solution, the retail chain reduced inventory costs by over 20% and improved product availability by 15%. By optimizing inventory levels, the retail chain was able to reduce carrying costs and improve inventory turnover, leading to significant cost savings.