Different screws and their uses can be produced through different methods. There are three main types of screws: straight, tapered, and special screws. The choice of the screw depends on the type of material to be fastened and the type of joint to be made.

Table of Contents

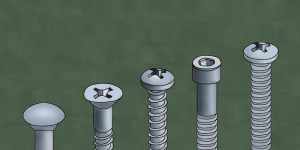

Common types of screws

There are many different examples of fasteners. Screws are a common type of fastener. The most common screws are the straight, tapered, and special screws.

Straight screws

Straight screws have a constant diameter along their length. They are used for materials that are difficult to fasten with a tapered screw, such as metal.

Tapered screws

Tapered screws have a diameter that decreases towards the tip. They are used for materials that are easy to fasten with a straight screw, such as wood.

Special screws

Special screws have non-standard shapes or dimensions. They are used for special applications, such as in electronic equipment.

The choice of the screw depends on the type of material to be fastened and the type of joint to be made. In general, straight screws are used for metal, tapered screws are used for wood, and special screws are used for special applications.

What is the difference between a screw and a bolt?

A screw is a type of fastener characterized by a helical ridge, known as a thread, that winds around the cylindrical shaft of the screw. The helical geometry allows the screw to be inserted into a hole in one direction and tightened or removed by rotating it in the opposite direction.

A bolt is also a type of fastener, but it features a square or hexagonal head that is rotated with a wrench to fasten or loosen it. The bolt’s shaft also has a threaded section, but the threads are designed to engage with matching holes in the nut or other part that it is being attached to, rather than mating with a hole in another object like a screw.

In most cases, screws are used in smaller applications where the bolt would be too large, and bolts are generally used in larger applications where the screw would be too small.

Different types of screw applications for aerospace

Screws are one of the most versatile and widely used fasteners in the aerospace industry. They come in a variety of sizes, shapes, and materials to suit a wide range of applications.

Some common types of screws used in aerospace applications include:

- Flat head screws: These screws have a flat head with a Phillips or slotted drive. They are used in a wide variety of applications, including joining sheet metal parts and fastening wood or plastic components.

- Pan head screws: These screws have a rounded head with a Phillips or slotted drive. They are often used to join thicker materials, such as metal plates.

- Button head screws: These screws have a flat head with a small, round depression in the center. They are typically used in applications where a low profile is desired, such as in electrical equipment.

- Machine screws: These screws have a cylindrical shaft and are available in a variety of thread pitches. They are used to fasten machine parts and components together.

- Socket head screws: These screws have a cylindrical shaft with a hexagonal socket in the head. They are often used in high-strength applications where a wrench is required to tighten or loosen the screw.

- Self-tapping screws: These screws have sharp threads that cut into the material, making them ideal for fastening light-gauge sheet metal.

- Sheet metal screws: These screws have sharp threads and a pointed tip, making them ideal for fastening sheet metal parts.

Different materials are used for different applications, depending on the strength and durability requirements. Common materials used for screws include steel, stainless steel, titanium, and aluminum.

Conclusion

There are many different types of screws available on the market, each with its own unique purpose and application. When choosing a screw for a particular project, it is important to consider the type of material to be fastened, the type of joint to be made, and the specific requirements of the project. With so many options available, there is sure to be a screw that is perfect for the job at hand.

Localisez via le logiciel système « Find My Mobile » fourni avec le téléphone ou via un logiciel de localisation de numéro de téléphone mobile tiers. https://www.mycellspy.com/fr/tutorials/how-find-my-partner-phone-activity-on-my-phone/

Les raisons les plus courantes de l’infidélité entre couples sont l’infidélité et le manque de confiance. À une époque sans téléphones portables ni Internet, les problèmes de méfiance et de déloyauté étaient moins problématiques qu’ils ne le sont aujourd’hui.