Deep hole drilling is the latest machining technology utilizing various natural and valuable resources. However, not every deep hole drilling process is successful. Still, to make ends meet and have a productive operation, it is essential to know the challenges facing deep-hole drilling and the solutions that might fit the problems. The main challenges with deep hole drilling in the defense industry include the cutting conditions, which operators cannot observe directly. Most issues can be corrected by:

- Listening to the sound produced while drilling

- Watching machine load and oil pressure

- Observing the chips and more

The inability to spread cutting heat is another challenge to the process. It’s also tricky to remove splinters; if they are blocked, they might lead to drilling bit damage.

In lieu of these challenges, working with an expert in defense deep hole drilling services will help optimize the chances of success. To get you started, we’ve prepared a list of tips to observe when carrying out deep-hole drilling operations.

- Meet All Drilling Parameters

There are a few things you must do to meet the requirements of deep hole drilling:

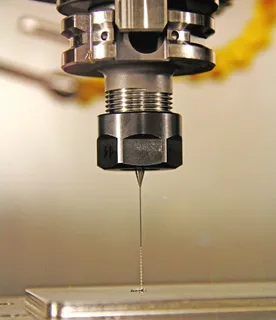

- First, the drill must have a center hole for delivering fluid to the tip, thus controlling the drilling temperature.

- To ensure your tool serves you for a long, use an automatic feeding tool. The end face of the workpiece has to be perpendicular to its axis to ensure the dependability of the end face cap.

- Also, the cutting fluid system should be clear, unblocked, and standard.

- Finally, the operator must keep the drill on the axis, and the drill must be precisely straight and symmetrical about its axis.

- Use Appropriate Cutting Fluid

The right amount of cooling fluid and pressure should be keenly observed since they’re essential subject to the deep hole diameter. A small drilling hole diameter might need a cooling fluid with higher viscosity but a higher pressure.

In the cutting process, a lot of heat escapes, affecting the drilling machine’s performance as it doesn’t easily diffuse. With this condition, the tools need enough cooling and lubricating fluids to maintain adequate performance. In this case, an extreme pressure emulsion or a 1:100 emulsion is perfect for the task. When surface quality, machining toughness materials, and high drilling accuracy are required, high concentration, extreme pressure emulsion or extreme pressure emulsion is applied.

The kinematic thickness of cutting oil is usually 10-20 cm2/s at 40 ℃. The flow rate of cutting fluid is 15-18 m/s. Always remember when a machining diameter is small, we use a cutting oil that has a low viscosity. For deep hole drilling that requires high precision, the ratio of cutting oils is 40% EP vulcanized oil + 20% chlorinated paraffin and 40% kerosene.

- Create a Guiding System

Before actual machining, a shallow hole is drilled first in the hole position of the workpiece to act as a guiding system and centering role during the drilling process. It is a form of the guide we refer to as “reaming.†It’s the countersinking of a pre-drilled hole, where the guide pads support the tool. Therefore, the tool geometry of these reamers is very similar to single-lip drills.

The difference between single-lip deep hole drilling with low cutting depth is the usually missing circumferential chamber alongside the cutting edge parallel to the milling axis and the low coolant volumes and pressures. The accuracy and precision of deep hole drilling are subject to the tools applied in the drilling process and their positioning.

If guiding elements in the liquid feeder and movable center support are worn out, they should be replaced quickly. The purpose is to avoid affecting drilling accuracy and accidents for operators. The question might be, how do we know that these elements are due for replacement? However, as mentioned earlier, operators always know this by listening to the sound produced and judging whether the pieces are worn out.

- Avoid Drilling on the Inclined Plane

No central hole should be on the machined end face of the workpiece. Drilling on the inclined plane should be avoided. Chip shape maintenance should be typical to prevent the formation of straight strip chips. Always ensure to apply a higher speed to process through the hole, and when the drill is about to drill through, reduce the rate or, equivalently, stop the machine to prevent drill damage.

- Avoid Drill Walking

This is achieved by stabilizing the drill hole before proper drilling. You’ll be sure to get your desired hole results with proper deep-hole drilling practice. Skiving and smooth rolling are among the best practices for deep hole drilling, as the two play a critical role in improving the dimensional accuracy of the borehole diameter. In addition, operators can create a suitable work site for subsequent machining processes such as honing and rolling.

- Invest in Special-Purpose Deep Hole Drill Bits

For longer holes, a special-purpose deep hole drill bit will have only one cutting edge rather than two. Additionally, this will play a significant role during chip removal. General checkups and routine maintenance services on critical areas of the deep-hole drilling machine are mandatory to avoid emergency maintenance during the work process.

Bottom Line

Following best practices and having the right tips for drilling is the way to achieve desirable results. With the above tips, the deep hole drilling process should be easy and without any challenges. Working with an expert in defense deep-hole drilling services will ensure challenges are mitigated effectively, and project success will be inevitable.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.