In the fast-paced world of modern electronics, every component plays a crucial role, and pogo pins are no exception. These tiny yet powerful connectors enable seamless communication between devices, ensuring reliability and efficiency in everything from smartphones to advanced robotics. Companies like Promax are at the forefront of this innovation, delivering high-quality pogo pin solutions that enhance device performance and drive the future of electronic design. Understanding the importance of pogo pins not only highlights their impact on device performance but also sheds light on the evolving landscape of modern electronics.

Table of Contents

Overview of Pogo Pins

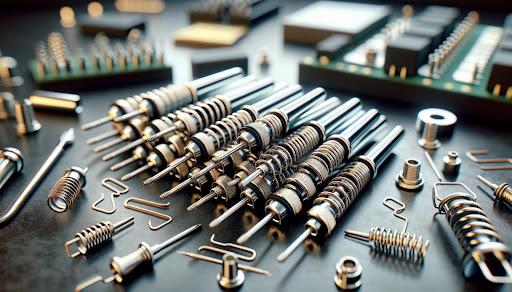

Pogo pins are spring-loaded connectors used extensively in modern electronics. They establish temporary electrical connections between devices, making them vital in various applications, such as diagnostics and programming. Their design includes a metal pin encased in a housing with a spring mechanism, enabling the pin to spring back when not in use.

These connectors serve multiple purposes, including:

- Testing: Pogo pins facilitate easy access to test points on circuit boards, streamlining the testing process of electronic components.

- Programming: They allow secure connections for programming devices, ensuring reliable data transfer during development and manufacturing.

- Charging: Pogo pins provide efficient solutions in charging applications for devices like wearable technology and electric vehicles.

Pogo pins demonstrate versatility through various configurations, including different lengths, diameters, and contact finishes. Their durability ensures they withstand repeated use without compromising performance. This reliability makes pogo pins essential in the growing landscape of modern electronic devices and systems.

Functionality of Pogo Pins

Pogo pins play a crucial role in establishing reliable electrical connections across numerous electronic applications.

Electrical Connections

Pogo pins provide secure electrical connections via spring-loaded mechanisms. They engage automatically when forced into contact with their counterparts, creating a stable link for data transmission or power transfer. This functionality suits various applications, including circuit testing, where accessing specific points on a motherboard is essential. Pogo pins ensure consistent connectivity even after multiple uses, which enhances the durability of the devices they connect. Their design minimizes the risk of wear due to repeated insertion and extraction, promoting long-term functionality.

Mechanical Design

Mechanical design elements of pogo pins contribute significantly to their effectiveness. Each pogo pin features a metal pin within a robust housing that incorporates a spring mechanism. This spring allows the pin to retract when not in contact, preventing damage and ensuring that the device remains compact and user-friendly. The materials used in their construction, typically stainless steel or copper alloys, improve resilience against corrosion and mechanical stress. Additionally, pogo pins come in various sizes and configurations, offering customization to meet specific design requirements in electronic devices. This adaptability makes them essential components in modern electronics, enabling manufacturers to integrate compact, efficient solutions into their products.

Applications of Pogo Pins in Electronics

Pogo pins play a crucial role in diverse electronic applications, enhancing functionality and reliability across various fields.

Consumer Electronics

Pogo pins are essential in consumer electronics, providing reliable connections for devices such as smartphones, tablets, and wearables. They support functions like charging, data transfer, and device programming. For example, pogo pins ensure efficient charging connections in smartwatches and fitness trackers. They facilitate battery testing and programming in manufacturing processes, streamlining device assembly and quality control. The compact design of pogo pins also allows for integration into space-constrained applications, making them suitable for thin devices without compromising performance.

Industrial Applications

Pogo pins are prevalent in industrial applications, offering secure connections in testing and diagnostics equipment. In automated testing systems, pogo pins establish temporary links to circuit boards, allowing engineers to verify functionality without permanent connectors. They withstand rigorous use in environments such as automotive testing and industrial machinery. Additionally, pogo pins enable quick-connect solutions for equipment maintenance, reducing downtime during repairs. Their durability and versatility in configuration support a wide range of industrial processes, from robotics to telecommunications, emphasizing their importance in modern automation and communication systems.

Advantages of Using Pogo Pins

Pogo pins offer several advantages that improve their usefulness in modern electronics.

Reliability and Durability

Pogo pins provide reliable connections due to their spring-loaded design, which ensures automatic engagement upon contact. This feature eliminates connectivity issues, crucial for applications requiring frequent insertion and removal, such as testing and programming electronic devices. With materials like stainless steel and copper alloys, pogo pins resist wear and corrosion, maintaining functionality over extended periods. Their robust construction withstands the rigors of repeated use without loss in performance, making them a preferred choice for both consumer and industrial applications.

Cost Efficiency

Pogo pins contribute to cost efficiency in electronic design and manufacturing. Their ability to facilitate quick connections reduces assembly time and labor costs, ultimately lowering overall production expenses. Manufacturers can customize pogo pin configurations to meet specific application needs, optimizing component use and minimizing waste. The longevity of pogo pins further enhances cost-effectiveness, as their durability decreases replacement frequency, providing long-term savings on materials and maintenance.

Conclusion

Pogo pins are integral to the advancement of modern electronics. Their unique design and functionality make them indispensable for ensuring reliable connections in a variety of devices. As technology continues to evolve, the demand for efficient and durable connectors like pogo pins will only increase.

In applications ranging from consumer electronics to industrial systems, pogo pins improve performance and streamline processes. Their ability to provide secure connections while minimizing wear and tear underscores their significance in the electronic landscape. Embracing pogo pins not only optimizes device functionality but also paves the way for innovative designs in the future.